- Home →

- Dynamic mounting systems

- Static system

- Uniaxial dynamic system, east-west

- Biaxial Dynamic System

We understand the importance of each additional percentage of energy generation for our customers, so the "system efficiency" parameter is a result of complex works on each system component as well as the application of modern materials, design and production technologies, anticorrosive protection, electronic control systems. The chart above illustrates the difference in energy generation when using different types of PV module mounting systems at the same installed capacity of the solar power plant.

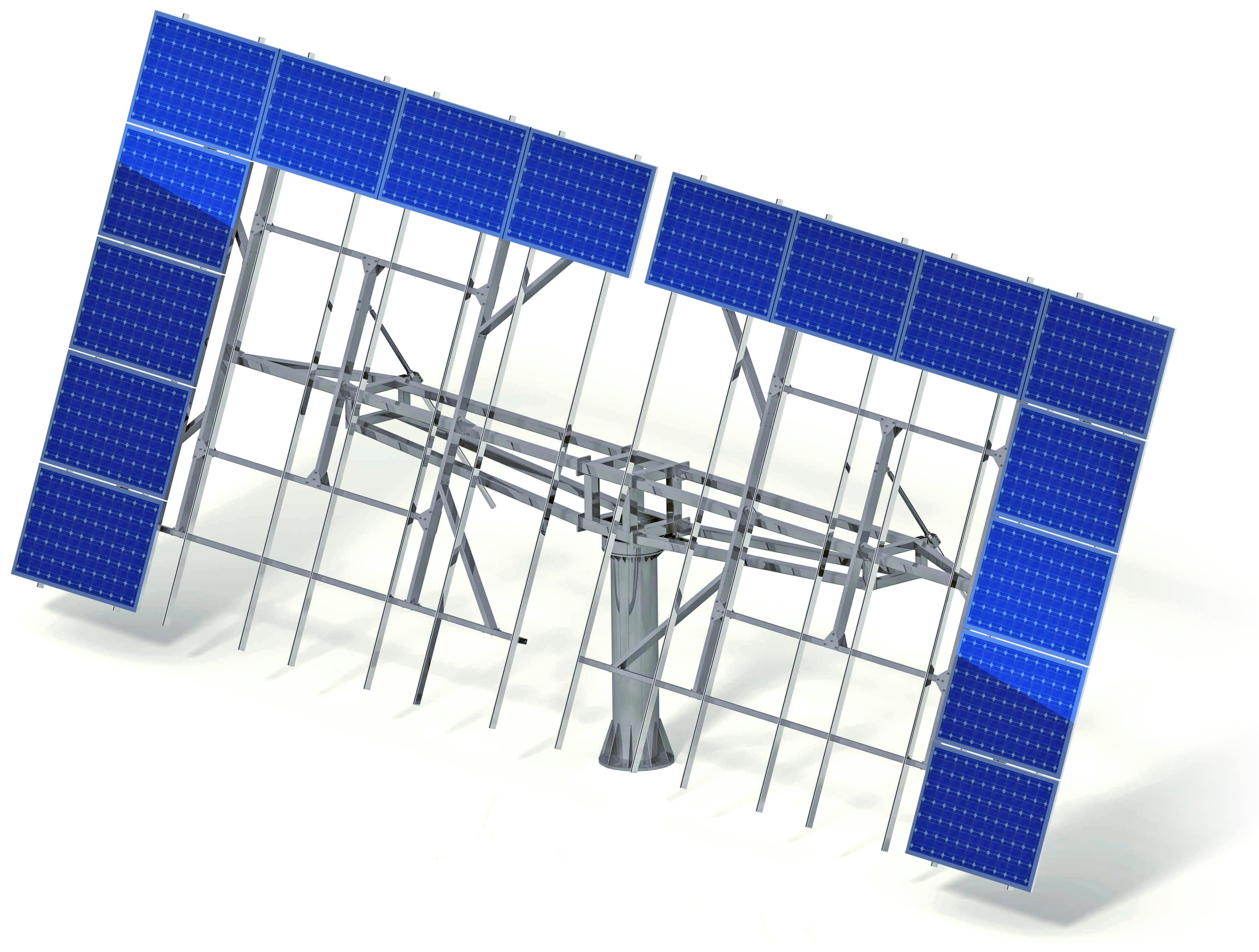

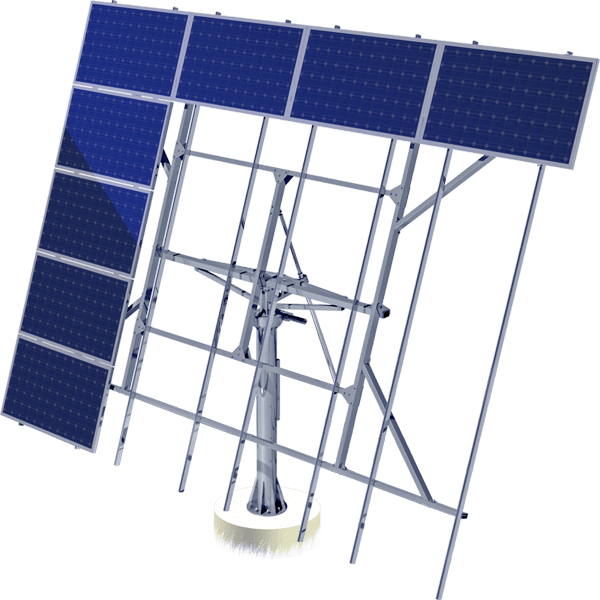

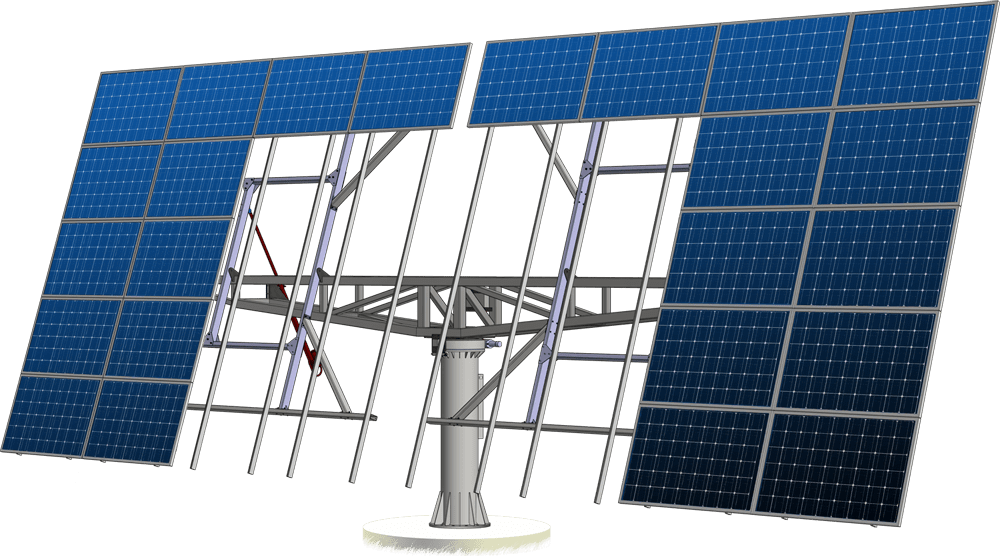

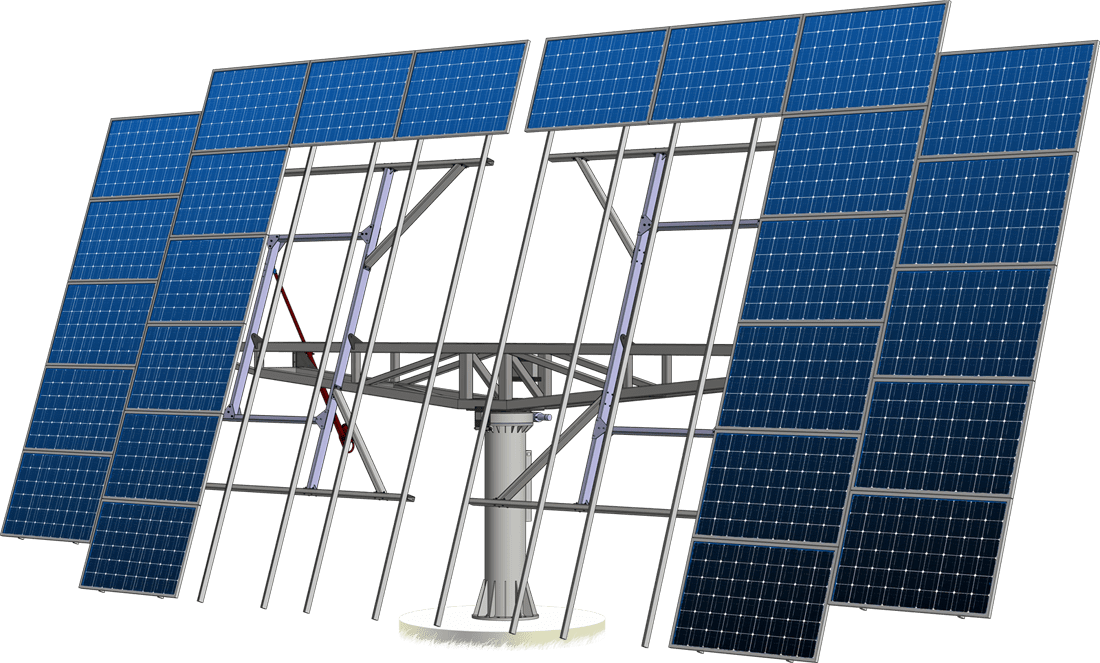

The dynamic PV module mounting systems allow using sun energy for power generation in the most effective way comparing to the static systems. Currently, Ukrainian System Solar has a whole range of dynamic PV mounting systems - single- and double-axis solar trackers.

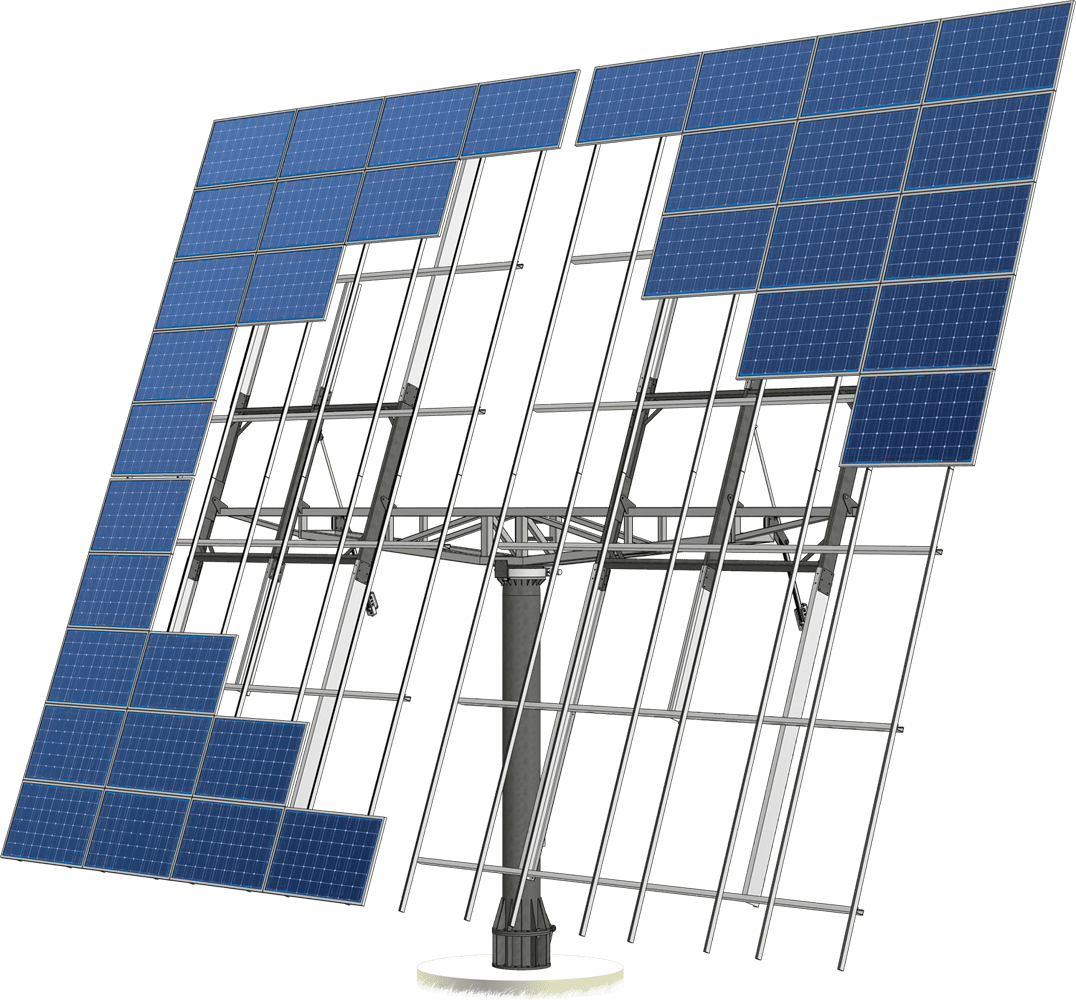

Double-axis trackers

- Ground-fixed installation

- For frame and frameless PV modules

- Installed capacity: up to 21 kW

- A slew-drive device for rotation on azimuth and an actuator - on the horizon

- Operating voltage: 100-260 V AC / 50-60 Hz

- Materials: hot-dip galvanized steel, aluminum, stainless steel

- 24/7 web monitoring of operation and technical state of trackers

Operating algorithm:

- Based on astronomical calendar

- Based on comprehensive sun irradiation sensor

Warranty:

- 10 years for steel and aluminum system components

- 2 years for active control system and electrical and mechanical equipment

Basic technical data of double-axis trackers

|

|

|

|

|

| Model | AS - 20 | AS - 40 | AS - 46 | AS - 80 |

| Nominal installed capacity, kW (PV module 270 W) | 5,40 | 10,80 | 12,42 | 21,60 |

| Maximum area of PV module allocation, m2 | 32,70 | 62,50 | 75,30 | 130,90 |

| Maximum sizes of PV module allocation (width х height), m | 6,60 x 5,00 | 13,50 x 5,00 | 13,50 x 6,02 | 13,50 x 10,29 |

| Azimuth angle of rotation | ± 120° | |||

| Zenith angle of rotation | 0 – 70° | |||

| Height of pillar (min. / max.), m | 2,18 / 4,28 | 1,92 / 4,00 | 1,92 / 4,00 | 4,40 |

| Distance from the ground to the low edge of PV module, mm | 500 / 2 560 | 500 / 2 566 | 60 / 2 060 | 850 |

| Materials | Galvanized steel, aluminum, stainless steel | |||

| Weight, kg | 600 | 1 887 | 1 900 | 2 250 |

| Fixing to a concrete foundation | Studs+ chemical anchor | Embedded anchor basket | Embedded anchor basket | Embedded anchor basket |

| Operating voltage | 100-260V AC / 50-60 Hz | |||

| Drives, (azimuthal/zenith rotation) | Slewing drive in enclosed housing / Actuator | |||

| Estimated figures of annual domestic consumption kW*h in year | 20 | 26 | 27 | 52 |

| Warranty |

10 years for steel and aluminum structures, 2 years for active control system and electrical and mechanical equipment |

|||

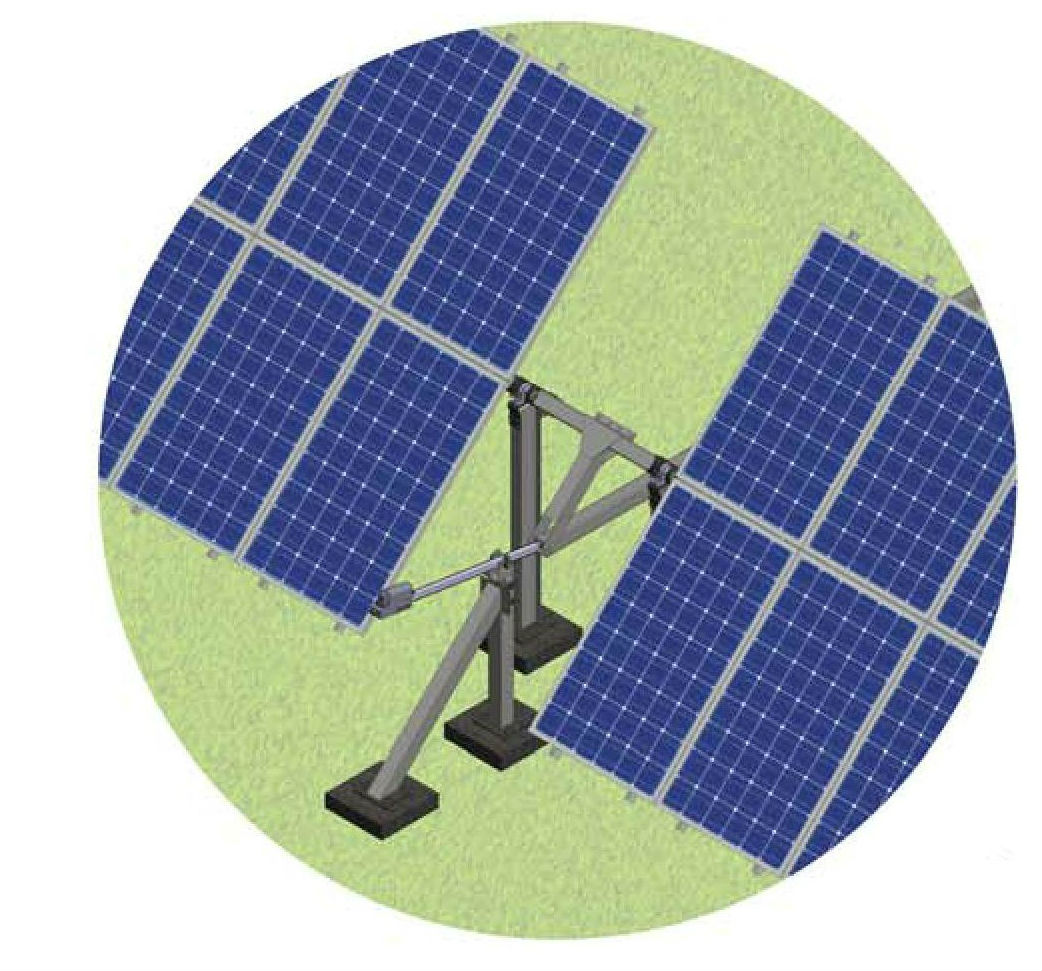

East-West single-axis tracker

- Ground-fixed installation on the concrete foundation

- Single-support mounting system

- For frame and frameless PV modules

- Portrait orientation of PV modules

- Inclination at ± 45 °

- Change of inclination by means of one actuator

- Operating voltage: 100-260V AC / 50-60 Hz

- Materials: hot-dip galvanized steel, aluminum, stainless steel

- 24/7 web monitoring of operation and technical state

Operating algorithm:

- Based on astronomical calendar

- Based on comprehensive sun irradiation sensor

Warranty:

- 10 years for steel and aluminum system components

- 2 years for active control system and electrical and mechanical equipment

Benefits of using single-axis tracker

- 30% increase in installed capacity of solar power plant

- 15-17% annual increase in energy generation

- 5% increase in the "green tariff" rate

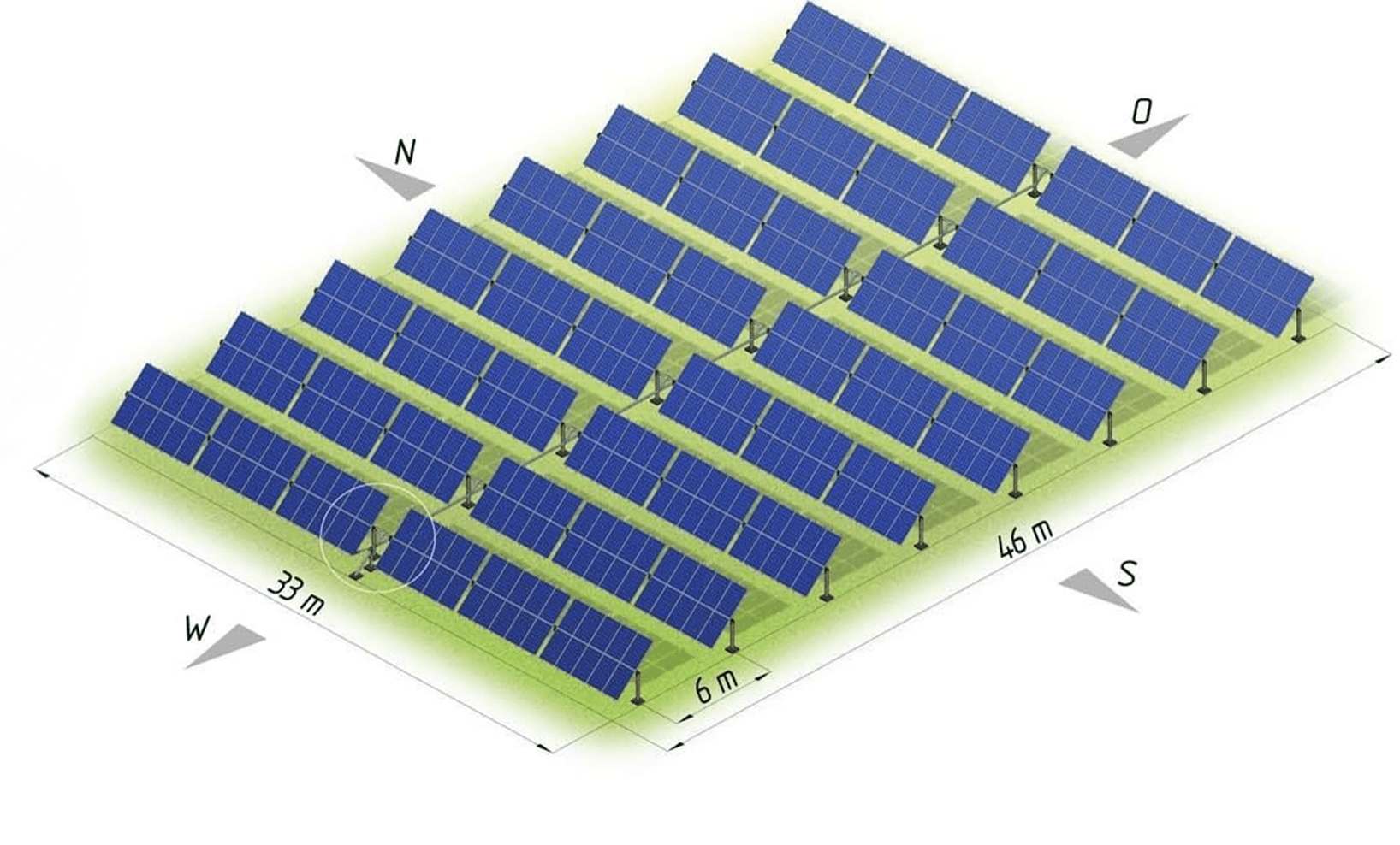

A single-axis solar tracker is a single-support dynamic PV mounting system that contains 8 sections of 60 PV modules in each. These 8 sections form a cluster of 480 PV modules of 140 kW installed capacity located on an area of 0.15 hectares. Moreover, it is possible to adapt the solar tracker to the land area of almost any shape.

|

|

Basic technical data of double-axis solar tracker

| Cluster installed capacity, kW | 129,6 |

| Number of PV modules (60-cell or 72-cell) in a section, pcs. | 60 |

| Number of sections in a cluster, pcs. | 8 |

| Number of PV modules in a cluster, pcs. | 480 |

| Land area under the cluster, m2 | 1 518 |

| Annual output, MW*h in year | 183,3 |

| Estimated figures of annual domestic consumption kW*h in year | 12 |

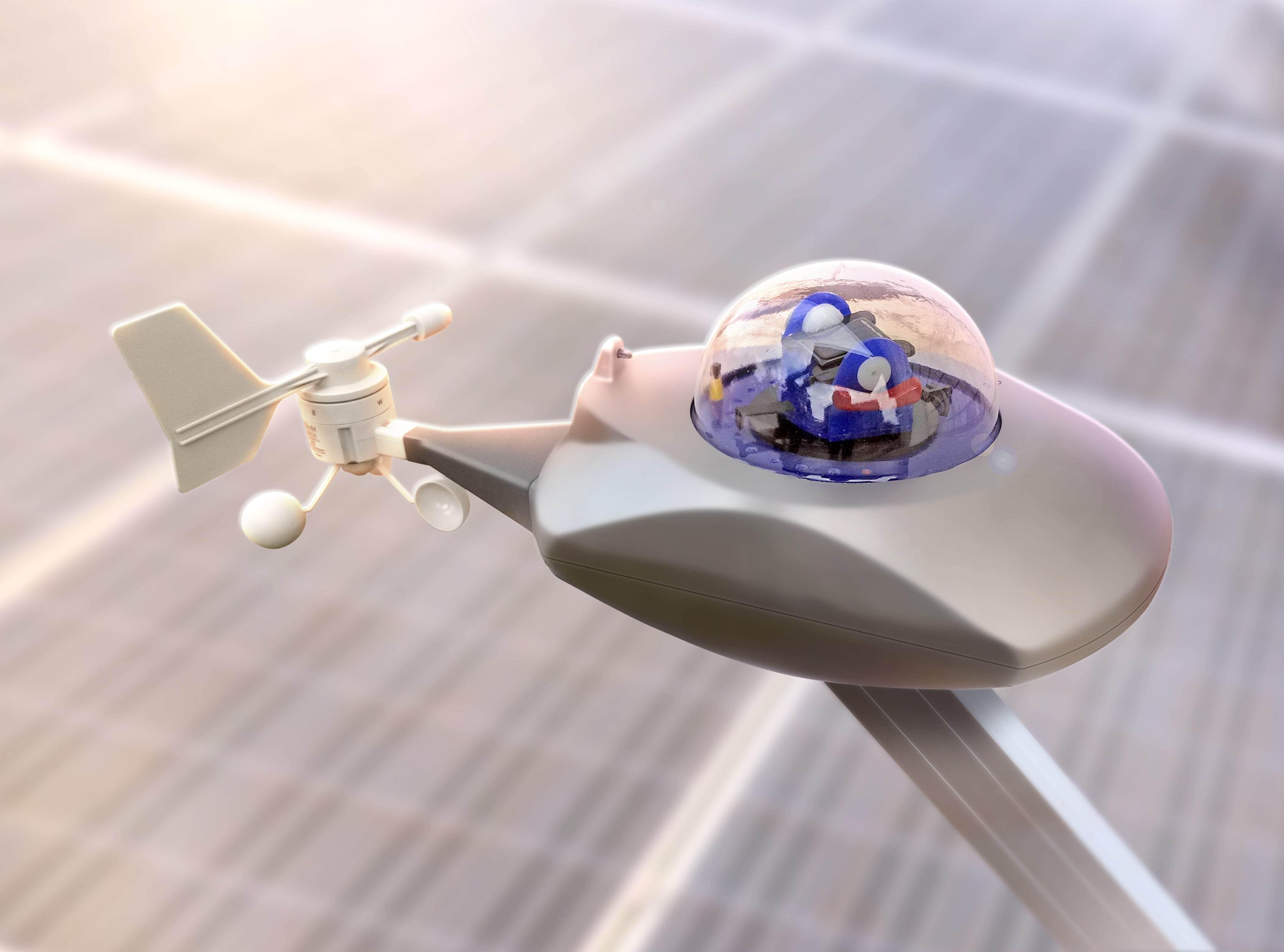

Control system

Maximum efficiency

The single- and double-axis solar trackers are equipped with the integrated control system and a comprehensive sun irradiation sensor that has proved itself at the projects delivery. To improve the reliability, the system operates in two modes: active and passive.

In regular (active) mode, the system using a comprehensive sun irradiation sensor continuously analyzes the state of the sun and irradiation and directs the array of PV modules to the area of the maximum energy saturation, taking into account the diffused and reflected light. That is especially important in cloudy and gloomy days when the sun is covered with clouds.

In passive mode, the system starts to operate in case of the sun irradiation sensor’s failure. In such case, the tracker operates on the astronomical calendar.

Thus, automatically changing the installation angle of the PV module array, with help of the integrated control system, the double-axis solar tracker provides an annual increase in energy generation compared to a static system of up to 50%, and a single-axis tracker - up to 15-17% per annum.

Operational reliability

Operational reliability

The complex control system provides reliable protection against wind and snow loads thanks to the integrated wind and snow sensor.

When the wind load exceeds the allowed values, the control system sets the PV module array to the feathering position (the smallest opposing the wind flow).

When the snowfall exceeds the defined allowance, the control system sets the PV module array to the position for the snow removal from its surface.

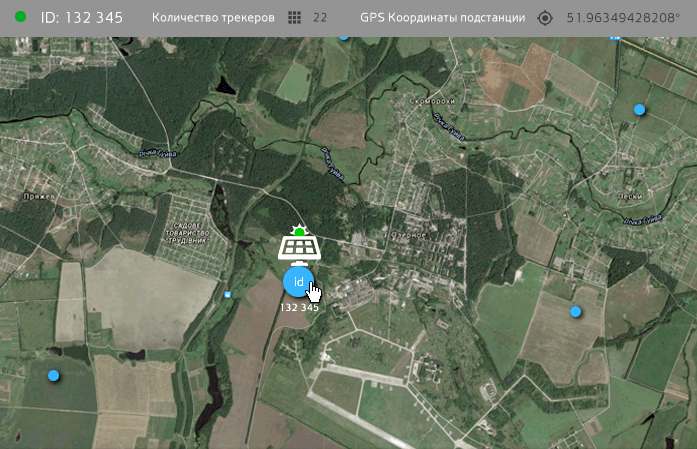

Monitoring

The system has 24/7 web monitoring function over the tracker’s operating condition.

The information on the tracker's technical condition is automatically transmitted by the control system to the dedicated server via the GPRS channel and displayed in the client's personal account on the company's web page. Thus, the solar tracker owner can remotely monitor its operation 24/7 from any location. The following options are available:

- Sun irradiation sensor status;

- Snow sensor status;

- Wind speed;

- Orientation of the tracker (azimuth, PV array inclination);

- Ambient temperature;

- Sun irradiation output.

Materials and standards

Aluminum elements of static PV mounting systems are manufactured of the high-quality extruded aluminum profile of AlMg0.7Si 6063T66 based on EN 755-2.

Steel elements are made of С235 steel under the National State Standard 27772-80 and covered with a protective hot dip galvanizing coating with a thickness of up to 70 μm. The coating meets the requirements of the National State Standard 9.307-89.

Fastening elements of mounting systems are supplied in options:

- stainless steel А2, А4 ISO 3506-1: 2009; ISO 3506-2: 2009

- carbon steel with zinc-dispersed coating Delta-MKS® ISO 10683: 2000, in the strength classes 5.8, 8.8 ISO 898-1: 2010.

A selection of materials used in the mounting systems fully eliminates corrosion degradation, including by electrochemical corrosion for at least 25 ÷ 30 years. A similar result has been achieved through a careful selection and reasonable combination of materials, as well as the use of protective new generation zinc- dispersed coatings Delta MKS®.

Static PV mounting systems manufactured by Ukrainian System Solar meet the requirements of the following standards:

- Ukraine’s National Building Code В.1.2-2-2006 “The reliability and security system of construction sites. Loads and impacts. Design standards”.

- Construction rules and regulations 2.01.01-82. “Building Climatology and Geophysics”.

- Ukraine’s National Building Code В.1.1-12: 2006 “Construction in seismic regions of Ukraine”.

- National State Standard 22233-2001 “Profiles extruded from aluminum alloys for enclosing building facilities. General specifications”.

- Construction rules and regulations “Design standards. Steel structures”.

- Construction rules and regulations 2.03.06-85 “Aluminum structures”.

- National Standards of Ukraine ISO 10683: 2009 “Fasteners. Non-electrolytic zinc coatings obtained using dispersed zinc. Technical specifications”.

- National State Standard 9.307-85 “Hot dip galvanizing coatings. General requirements and methods of control”.

|

|

|