- Home →

- Standard solutions

Static PV module mounting systems with possibility of PV array inclination (25 °, 30 °, 35 °)

Ground-fixed static mounting systems have most widely used both for industrial power plants projects and for private households. Their main advantage - easy installation and low cost.

As a rule, PV mounting systems are designed directly for the customer requirements, taking into account the construction site specifics, its geodetic and geological survey, the wind loads and seismic activity of the area.

However, our company's engineers have developed the tailor-made solutions that can be immediately implemented in the operation, considering the customer's preferences.

The standard solutions developed by our experts are a "constructor" that makes it possible to install the PV modules in almost any way requested by the customer. Using the standard systems suggested by us, it is possible to assemble almost any PV mounting kit.

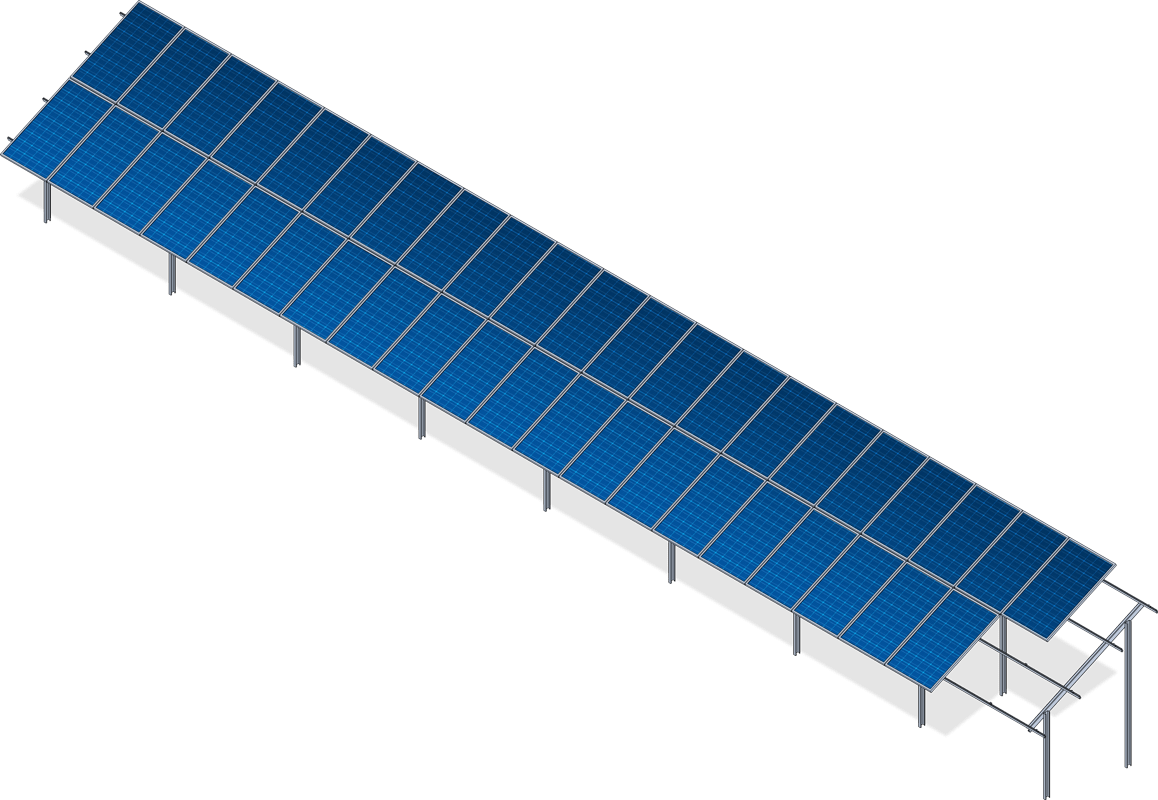

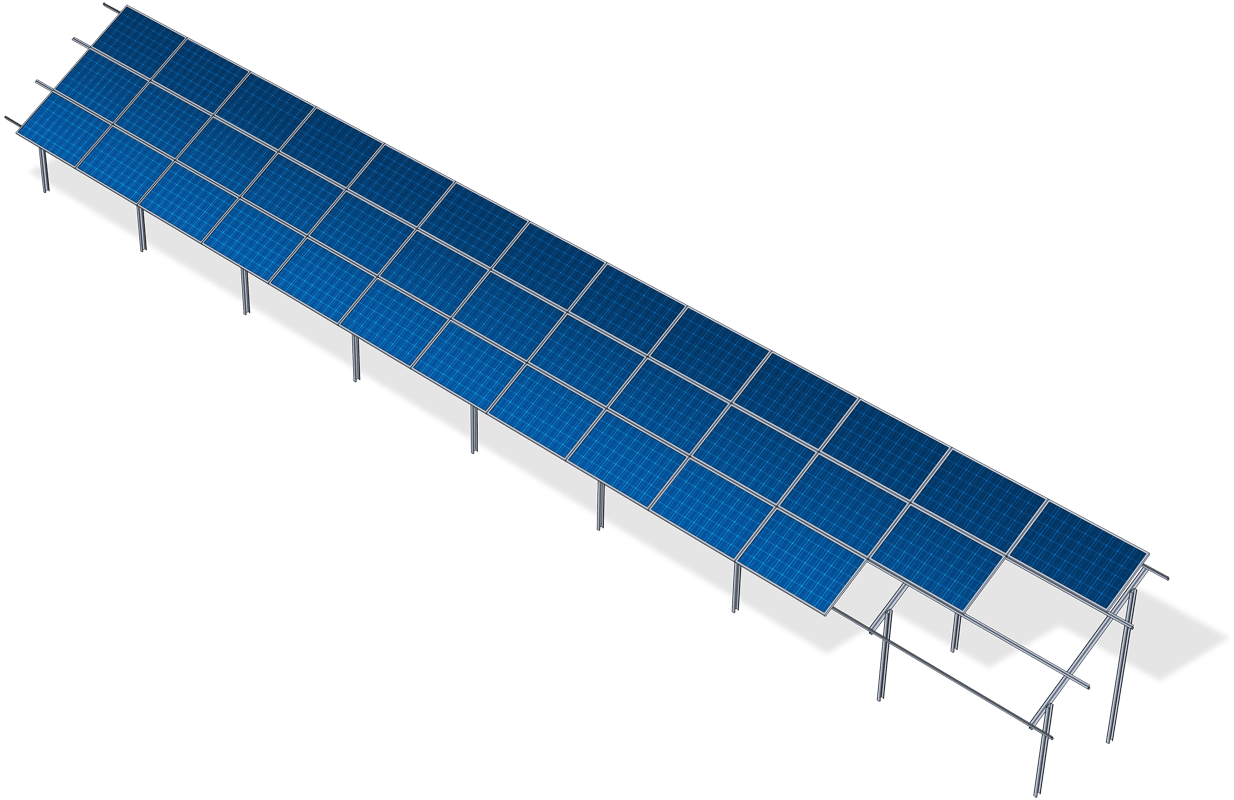

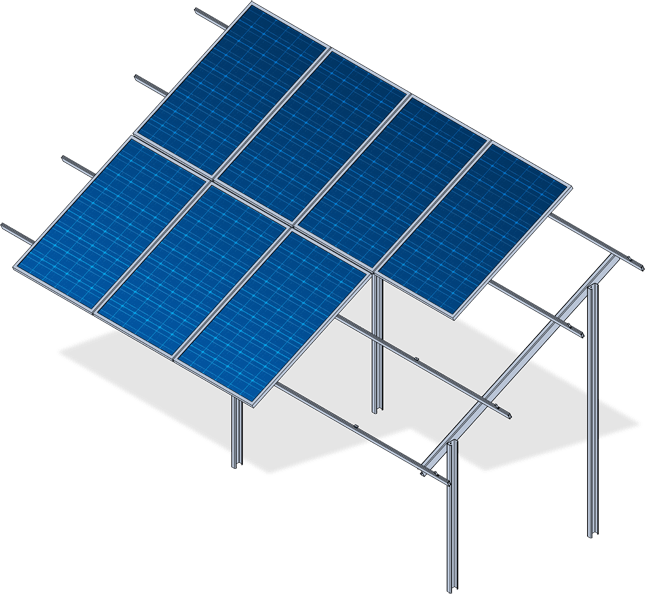

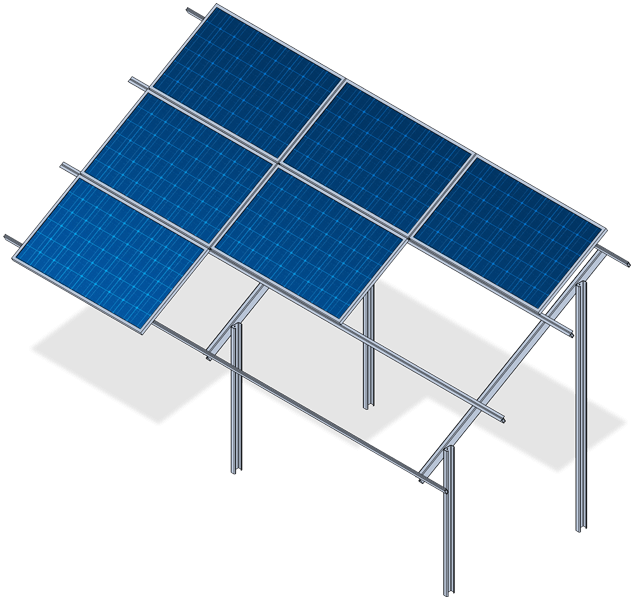

PV module installations "SSU-44" and "SSU-39" are universal systems intended for mounting frame photovoltaic modules in open areas. The systems are developed for two-row portrait and three-row landscape installation of frame photovoltaic modules at 25°, 30°, 35° inclination (installation dimensions to be selected accordingly).

- Ground-fixed mounting systems

- Availability in the company’s stock

- Fast delivery

- For all types of soils

- Portrait and landscape orientation of the PV modules

- Option to select inclination - 25 °, 30 °, 35 °

- High strength and reliability of structures

- Light weight of structures

- Quick installation

- Low labor input for installation work

- No need in highly qualified installation staff

- Up to 15 years of warranty

|

|

|

|

Basic technical data of SSU-44, SSU-39 systems

| Type of system | SSU - 44 | SSU - 39 |

| Place of installation | Ground | Ground |

| Method of pile installation | Concreting | Concreting |

| Number of bearing piles in a row | 9 pcs. | 9 pcs. |

| Module orientation, fixing scheme (row/mod.) | Portrait, 2x22 | Landscape, 3x13 |

| Number of PV modules | 44 | 39 |

| PV module tilt angle | 250; 300; 350 | 250; 300; 350 |

| Distance from the module low edge to the ground | 500 mm | 500 mm |

Materials used:

1. Bearing system elements are made of the anodized aluminum AlMg0.7Si 6063 T66 in accordance with the National State Standard 22233-2001, the thickness of the anodic-oxide coating is not less than 20 μm.

2. Support racks (rack profile "C +") are made of the hot-dip galvanized steel C235 in accordance with the National State Standard 27772-88 (the thickness of zinc coating is at least 40 μm).

3. Fastening elements:

- А2-70 stainless steel based on the State Standard of Ukraine ISO 3506-1: 2006;

- Carbon steel with zinc-dispersed coating “DELTA MKS”.

Such selection of materials provides a long period of operation (at least 25 years) with minimal maintenance support.

SSU system design allows simple, quick and safe installation without the use of special tools and does not require the involvement of highly qualified installation staff.

SSU system meets the requirements and standards applied at the time of delivery for safety and ecology.

|

|

|