- Home →

- Static mounting systems

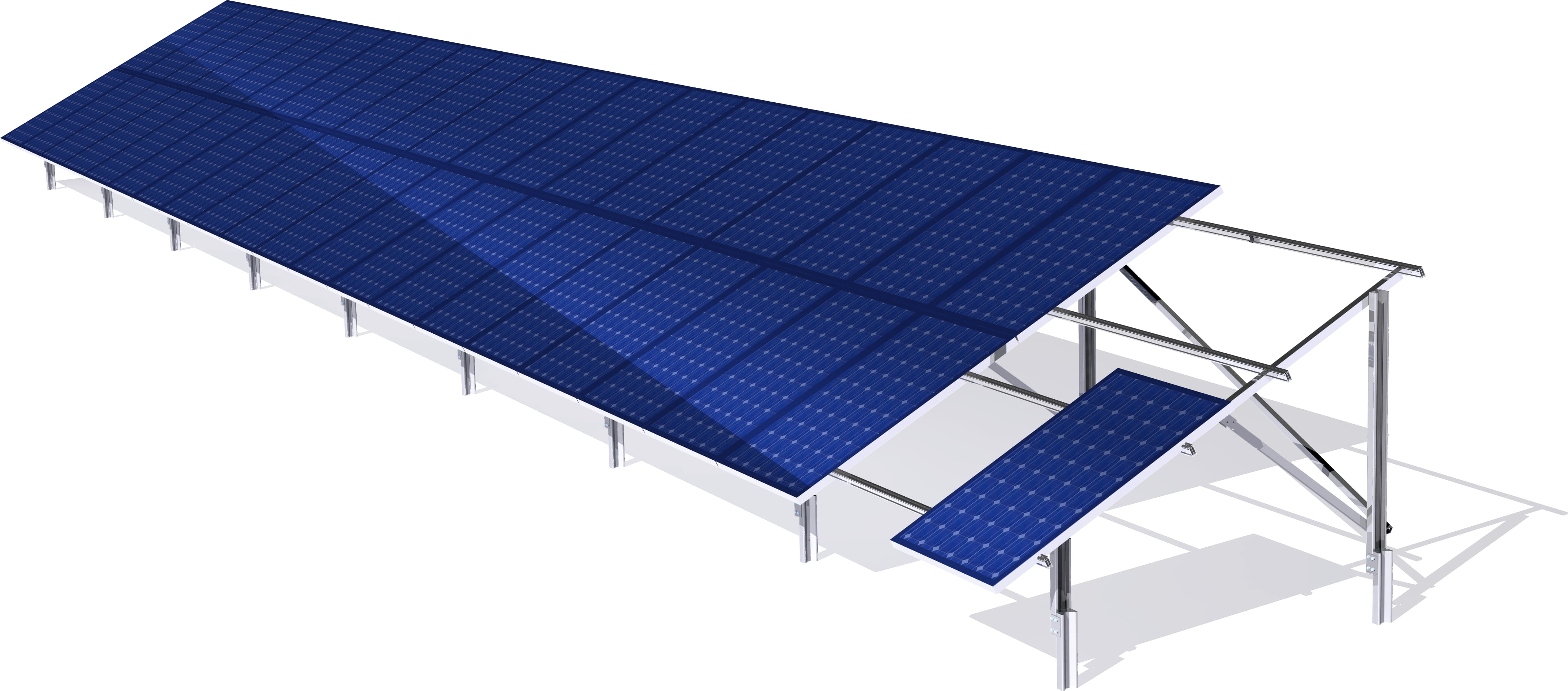

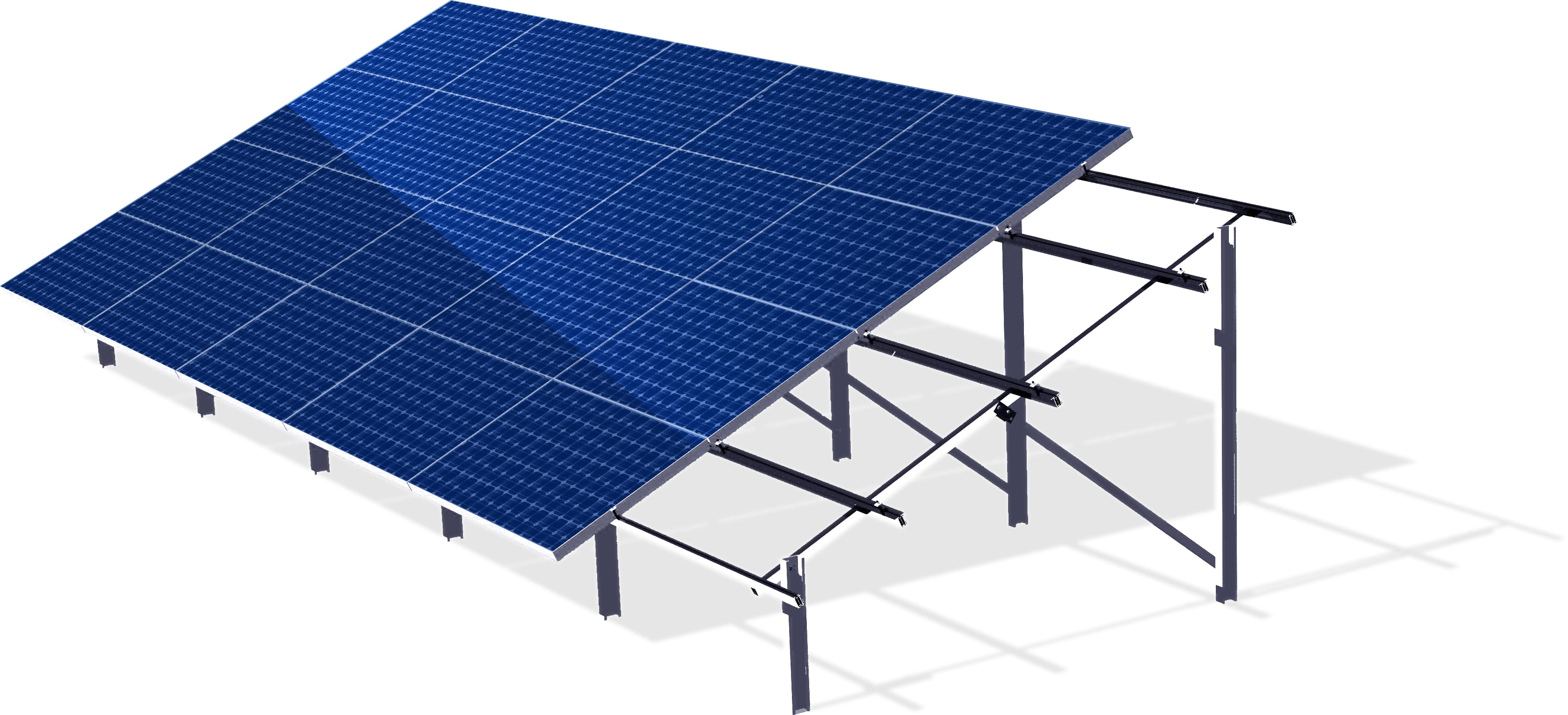

Ground-fixed static mounting systems

This type of PV mounting systems has been most widely used in Ukraine. The number of PV modules on one base array is generally 10-76 pcs. The total length of the array is limited to the shape of the land plot, the selection of inverters and the general project design of the solar power plant. The installation angle, the number of supporting racks is determined by the geographical location and soil characteristics.

This type of PV mounting systems has been most widely used in Ukraine. The number of PV modules on one base array is generally 10-76 pcs. The total length of the array is limited to the shape of the land plot, the selection of inverters and the general project design of the solar power plant. The installation angle, the number of supporting racks is determined by the geographical location and soil characteristics.

- For all soil types

- Mounting systems for seismic zones

- Single- and double-support mounting systems

- Single- and multi-row mounting systems

- Portrait and landscape orientation of PV modules

- For frame and frameless PV modules

- Inclination angle of PV module array 10-70 °

- High durability and reliability of systems design

- Light weight of systems

- Quick installation

- Low labor input for installation works

- No need for highly qualified staff to perform installation

- Up to 15 years of warranty

|

|

|

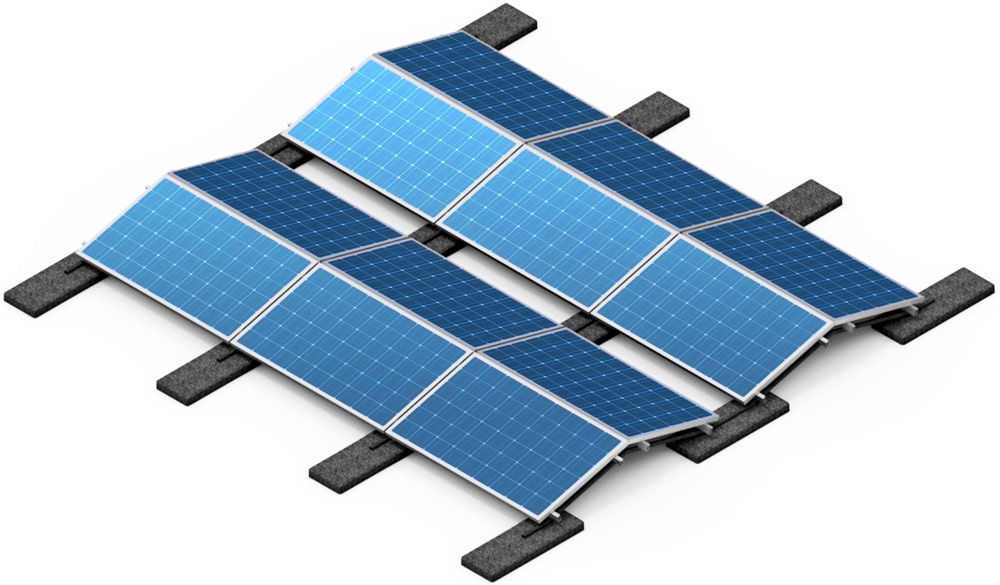

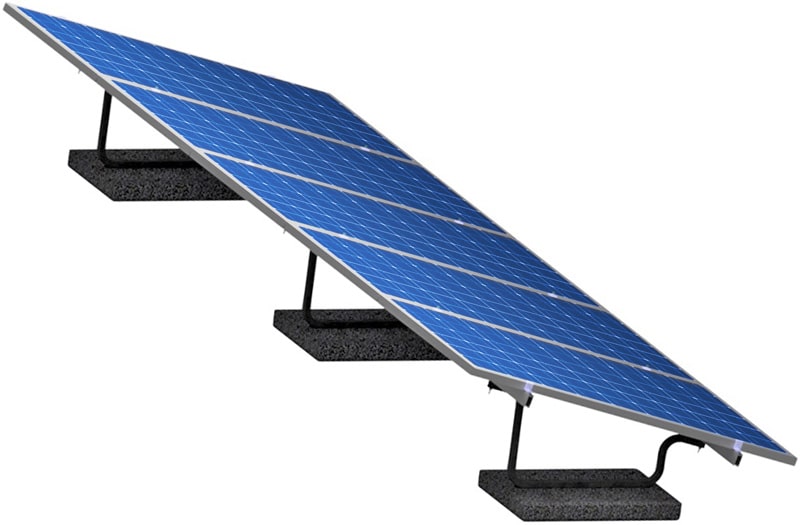

Static roof mounting systems

Roof mounting systems have a variety of types and mostly depend on the roof design. They can be either the ballast (flat roofs) or the anchor type (pitched and flat roofs). The array configuration - the number and orientation of PV modules, installation angle, type of mounting systems, etc. also depend on the roof. There are no standard solutions for the roof systems, each one is specific.

Roof mounting systems have a variety of types and mostly depend on the roof design. They can be either the ballast (flat roofs) or the anchor type (pitched and flat roofs). The array configuration - the number and orientation of PV modules, installation angle, type of mounting systems, etc. also depend on the roof. There are no standard solutions for the roof systems, each one is specific.

- For all roof types

- Single- and multi-row mounting systems

- Portrait and landscape orientation of PV modules

- For frame and frameless PV modules

- High durability and reliability of mounting systems

- Minimum interference in the roof design

- Light weight of mounting systems

- Quick installation

- No need for highly qualified staff to perform installation

- Up to 15 years of warranty

|

|

Materials and standards

Aluminum elements of static PV mounting systems are manufactured of the high-quality extruded aluminum profile of AlMg0.7Si 6063T66 based on EN 755-2.

Steel elements are made of С235 steel under the National State Standard 27772-80 and covered with a protective hot dip galvanizing coating with a thickness of up to 70 μm. The coating meets the requirements of the National State Standard 9.307-89.

Fastening elements of mounting systems are supplied in options:

- stainless steel А2, А4 ISO 3506-1: 2009; ISO 3506-2: 2009

- carbon steel with zinc-dispersed coating Delta-MKS® ISO 10683: 2000, in the strength classes 5.8, 8.8 ISO 898-1: 2010.

A selection of materials used in the mounting systems fully eliminates corrosion degradation, including by electrochemical corrosion for at least 25 ÷ 30 years. A similar result has been achieved through a careful selection and reasonable combination of materials, as well as the use of protective new generation zinc- dispersed coatings Delta MKS®.

Static PV mounting systems manufactured by Ukrainian System Solar meet the requirements of the following standards:

- Ukraine’s National Building Code В.1.2-2-2006 “The reliability and security system of construction sites. Loads and impacts. Design standards”.

- Construction rules and regulations 2.01.01-82. “Building Climatology and Geophysics”.

- Ukraine’s National Building Code В.1.1-12: 2006 “Construction in seismic regions of Ukraine”.

- National State Standard 22233-2001 “Profiles extruded from aluminum alloys for enclosing building facilities. General specifications”.

- Construction rules and regulations “Design standards. Steel structures”.

- Construction rules and regulations 2.03.06-85 “Aluminum structures”.

- National Standards of Ukraine ISO 10683: 2009 “Fasteners. Non-electrolytic zinc coatings obtained using dispersed zinc. Technical specifications”.

- National State Standard 9.307-85 “Hot dip galvanizing coatings. General requirements and methods of control”.

|

|

|

|